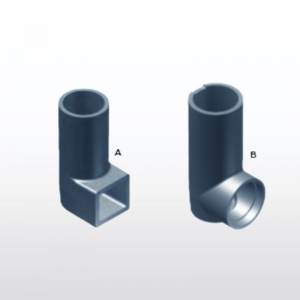

Bottom pour crucible

Features

Product Description:

Introduction:

Our Bottom Pour Crucibles are engineered for exceptional performance in the metal smelting industry. With a focus on reliability and efficiency, these crucibles provide the perfect solution for professionals seeking quality and precision in their casting processes.

Product Material Composition:

Crafted from high-purity silicon carbide and graphite, our Bottom Pour Crucibles undergo advanced processing techniques to guarantee stable quality. This premium material ensures longevity and durability under high-temperature conditions.

| Product Features | Description |

|---|---|

| Superior Heat Resistance | Designed to withstand temperatures up to 1800°C, ensuring safety during operations. |

| Efficient Pouring Mechanism | Facilitates precise pouring, reducing waste and improving overall efficiency. |

| Durability and Longevity | Engineered for long-term use, reducing the need for frequent replacements. |

| Lightweight Design | Enhances ease of handling, making it ideal for high-volume production. |

Applications:

Our Bottom Pour Crucibles are versatile and widely used in various sectors:

- Metal Smelting: Perfect for melting aluminum, copper, and other alloys.

- Chemical Experiments: Reliable for sample heating and reactions in laboratories.

- Material Sintering: Essential for high-temperature treatments in manufacturing.

Maintenance Tips for Longevity:

To maximize the lifespan of your crucibles, consider these essential maintenance practices:

- Cleaning Protocols: Regularly clean both the interior and exterior to prevent contamination.

- Temperature Management: Gradually preheat to avoid sudden thermal shocks that can lead to cracking.

- Regular Inspections: Routinely check for wear and damage to ensure consistent performance.

Frequently Asked Questions (FAQ):

- What temperature can a Bottom Pour Crucible withstand?

Our crucibles can endure temperatures up to 1800 degrees Celsius, showcasing outstanding heat resistance. - How should I clean my Bottom Pour Crucible?

We provide a detailed maintenance manual to guide you through proper cleaning methods. - In what applications are Bottom Pour Crucibles utilized?

These crucibles are utilized in metal smelting, chemical reactions, and sintering processes across various industries.

Conclusion:

By integrating our Bottom Pour Crucibles into your operations, you will experience enhanced efficiency, reduced waste, and a significant boost in productivity. Our commitment to quality ensures that you receive products designed to meet the high standards of the industry.

Call to Action (CTA):

Contact us today for a personalized quote or explore our complete product range to find the perfect solution for your metalworking needs! Let us help you elevate your casting processes with our high-performance Bottom Pour Crucibles.