Clay Graphite Crucible

Features

1. Introduction

Elevate your metal casting operations with our Clay Graphite Crucible! Designed for performance, these crucibles ensure efficient melting and casting for various applications, setting a new standard in the industry.

2. Material Composition

Crafted from high-quality clay graphite, our crucibles offer:

- Exceptional Thermal Conductivity: Ensures quick and even melting.

- Thermal Shock Resistance: Capable of withstanding sudden temperature changes without cracking.

- Chemical Stability: Resistant to reactions with molten metals, maintaining integrity and purity.

3. Key Applications

- Jewelry Manufacturing: Ideal for melting precious metals like gold and silver, perfect for creating intricate designs.

- Foundry Industry: Suitable for non-ferrous metals such as aluminum, copper, and brass, ensuring high-quality castings.

- Laboratory Research: Essential for high-temperature melting experiments in materials science.

- Artistic Casting: Perfect for artists needing reliable tools for metal sculptures and art pieces.

4. Operational Guidelines

- Preheating: Gradually preheat the crucible to 500°C before use to avoid thermal shock.

- Loading and Melting: Fill the crucible with metal, then raise the furnace temperature to the metal’s melting point. The crucible’s design ensures uniform melting.

- Pouring: Safely pour melted metal into molds using appropriate tools, ensuring accuracy and safety.

5. Advantages of Our Clay Graphite Crucibles

- High Thermal Conductivity: Accelerates the melting process, saving time and energy.

- Longevity: Designed for durability, our crucibles last longer than standard alternatives.

- Cost-Effectiveness: Reliable performance at competitive prices, ensuring excellent investment value.

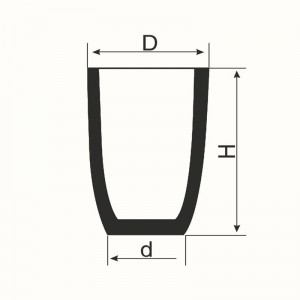

6. Technical Specifications

|

Item |

Code |

Height |

Outer Diameter |

Bottom Diameter |

|

CA300 |

300# |

450 |

440 |

210 |

|

CA400 |

400# |

600 |

500 |

300 |

|

CA500 |

500# |

660 |

520 |

300 |

|

CA600 |

501# |

700 |

520 |

300 |

|

CA800 |

650# |

800 |

560 |

320 |

|

CR351 |

351# |

650 |

435 |

250 |

7. Maintenance and Care Tips

- Handling: Inspect for cracks before use; store in a dry place.

- Post-Use: Allow to cool to room temperature; remove impurities gently to extend lifespan.

- Avoid Overloading: Do not exceed the crucible’s capacity to prevent cracking.

8. FAQ Section

- Q1. Can you accommodate custom specifications?

- Yes, we can modify crucibles to meet your specific requirements.

- Q2. What is your sample policy?

- We offer samples at a special price; customers cover sample and courier costs.

- Q3. Do you test all products prior to delivery?

- Yes, we perform 100% testing to ensure product quality.

- Q4. How do you maintain long-term business relationships?

- We prioritize quality, competitive pricing, and effective communication, treating every customer as a valued partner.

9. Why Choose Us

Our company is committed to providing top-tier clay graphite crucibles. We source high-quality materials, offer customization, and ensure exceptional customer support. With a focus on quality and competitive pricing, we aim to be your trusted partner in metal casting.

Transform your casting processes today! Contact us to learn more about our Clay Graphite Crucibles and how they can enhance your operations.