Crucible For Metal Casting

Features

Crucibles play a critical role in metal casting, ensuring smooth and efficient melting processes. We offer crucibles for metal casting engineered using isostatic pressing technology to meet the high-performance demands of industrial foundries. Isostatic pressing allows for the production of crucibles with uniform density and superior structural integrity, making them ideal for high-temperature and heavy-duty casting applications.

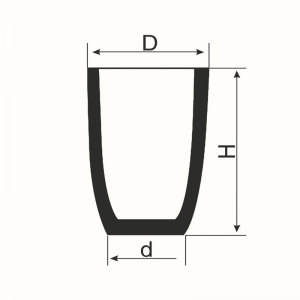

Crucible size

|

Model |

No. |

H |

OD |

BD |

| RN250 | 760# | 630 | 615 | 250 |

| RN500 | 1600# | 750 | 785 | 330 |

| RN430 | 1500# | 900 | 725 | 320 |

| RN420 | 1400# | 800 | 725 | 320 |

| RN410H740 | 1200# | 740 | 720 | 320 |

| RN410 | 1000# | 700 | 715 | 320 |

| RN400 | 910# | 600 | 715 | 320 |

Standard Parameters and Performance Analysis

To further demonstrate the high performance of our crucibles, we’ve conducted comprehensive testing on key parameters:

| Standard Parameter | Test Data |

|---|---|

| Temperature resistance ≥ 1630 ℃ | Temperature resistance ≥ 1635 ℃ |

| Carbon content ≥ 38% | Carbon content ≥ 41.46% |

| Apparent porosity ≤ 35% | Apparent porosity ≤ 32% |

| Volume density ≥ 1.6g/cm³ | Volume density ≥ 1.71g/cm³ |

These results illustrate the outstanding quality of our crucibles, which not only meet but exceed the standard parameters expected in the casting industry. The higher temperature resistance and carbon content provide better performance in high-temperature applications, while lower apparent porosity ensures higher mechanical strength.

Choosing the Right Crucible for Your Metal Casting Process

Our crucibles are offered in two primary types: graphite clay crucibles and silicon carbide graphite crucibles. Here’s how to choose the right crucible for your metal casting process:

- Graphite Clay Crucibles: Suitable for low to medium-temperature applications like casting copper or precious metals. These crucibles provide excellent heat retention and are cost-effective.

- Silicon Carbide Graphite Crucibles: Best for high-temperature casting, especially for non-ferrous metals like aluminum. With faster heat transfer, these crucibles offer enhanced thermal shock resistance and corrosion resistance, making them ideal for more demanding applications.

Crucibles for Metal Casting

With over 15 years of experience in the crucible manufacturing industry, our company is known for producing high-quality metal casting crucibles using state-of-the-art production processes. We specialize in both graphite clay crucibles and silicon carbide graphite crucibles, catering to diverse industrial needs worldwide.

Our isostatic pressing technology ensures the highest level of quality, delivering crucibles that are not only durable but also competitively priced. We proudly export our products to countries such as Vietnam, Thailand, Malaysia, Indonesia, and Pakistan, where our crucibles are recognized for their superior performance compared to international brands.

Selecting the right crucible for metal casting is critical to ensuring optimal efficiency and productivity in your foundry operations. With isostatic pressed crucibles, you get top-notch durability, thermal resistance, and cost-effectiveness. Our extensive experience and commitment to quality make us a trusted supplier for foundries around the world.

Contact us today to learn more about how our metal casting crucibles can enhance your production process. Let us help you find the perfect crucible solution tailored to your specific needs.