Lorem ipsum dolor sit amet consectetur adipiscing elit.

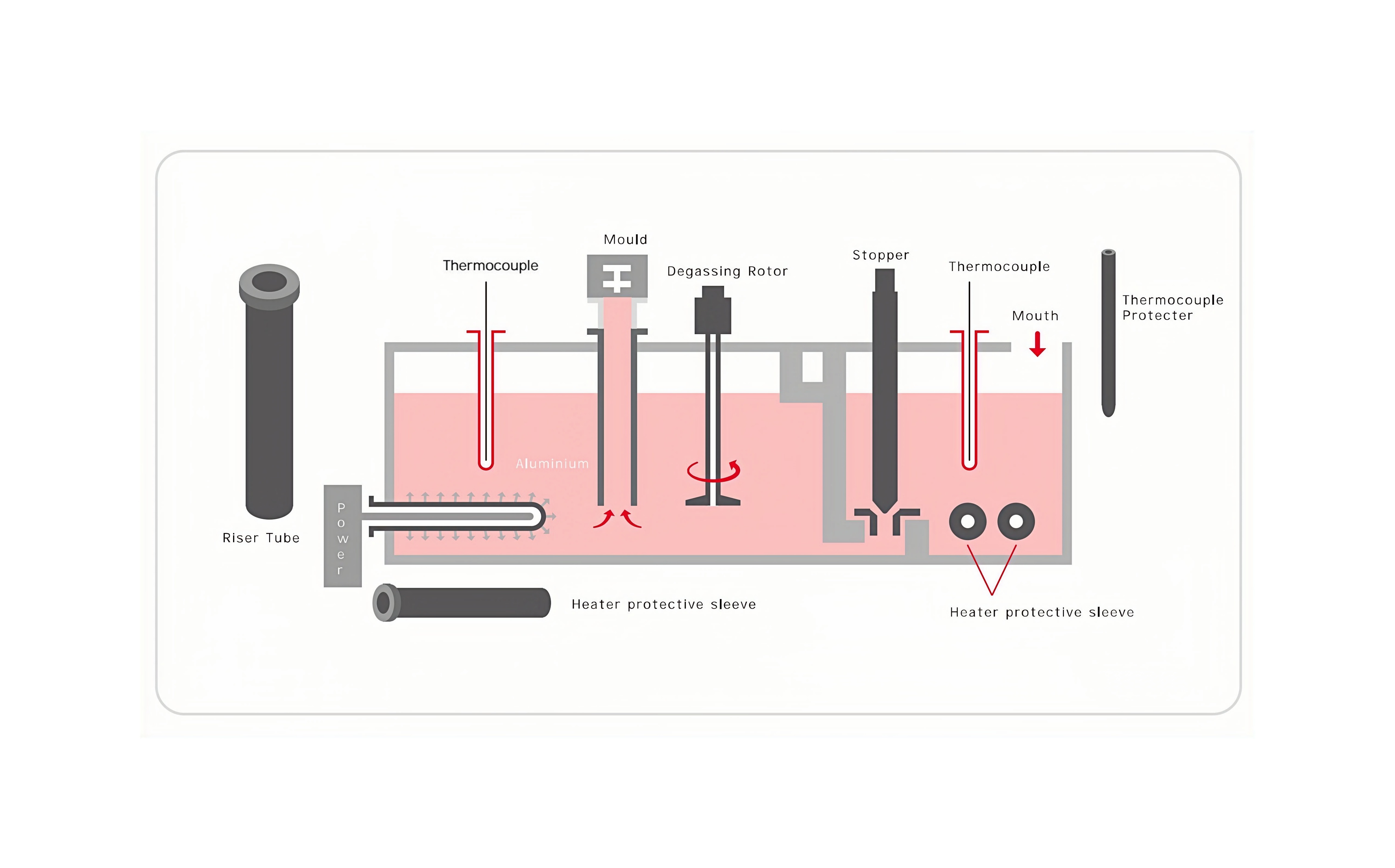

Silicon Nitride Degassing Rotor in Degassing Machine for Aluminium Foundry

High Strength Material

High Wear Resistance

High Corrosion Resistance

Core Features

The silicon nitride degassing rotor, with silicon nitride as its core material, integrates ultra - high - speed design and precise structural control, achieving performance breakthroughs in the degassing process of aluminum processing. Its core features are as follows:

I. Material Advantages: Temperature Resistance, Wear Resistance, and No Contamination

- Inherent Superiority Over Graphite: The rotor and impeller are made of silicon nitride. Its processing precision and strength far surpass those of graphite, supporting ultra - high - speed rotation (up to 8,000 rpm) and significantly extending the service life.

- High - Temperature Oxidation Resistance: There is almost no oxidation in high - temperature environments, completely avoiding the problem of “contaminating molten aluminum” and ensuring product purity.

- Chemical Inertness: It does not react with molten aluminum, stably maintaining the optimal degassing effect for a long time. There is no need to worry about material degradation affecting performance.

II. Structural Precision: Stable High - Speed Operation, Flat Molten Surface

- Ultra - High Concentricity: The concentricity of the rotor is strictly controlled within 0.2 mm (where 1 “silk” = 0.01 mm). During high - speed rotation, the vibration is extremely small, eliminating liquid surface fluctuations caused by eccentricity.

- Precision Connection System: The rotor head and the connecting shaft are made of stainless steel, with a processing precision reaching the 0.01 - mm level. Combined with high - precision assembly, “concentric high - speed driving” is achieved, minimizing the fluctuation of the molten aluminum surface and ensuring production stability.

III. Performance Upgrades: Efficiency, Reliability, and Cost Reduction

- High Density + High Strength: These two properties ensure structural reliability and no deformation risk during ultra - high - speed operation, making it adaptable to extreme working conditions.

- Distinct Comparative Advantages: Compared with graphite rotors, it takes a comprehensive lead in service life, pollution resistance, and high - speed adaptability. It reduces the frequency of shutdown maintenance and indirectly improves production efficiency.

Technical Specifications

| Features | Benefits |

|---|---|

| Material | High-density graphite |

| Maximum Operating Temperature | Up to 1600°C |

| Corrosion Resistance | Excellent, maintaining the integrity of molten aluminum |

| Service Life | Long-lasting, suitable for repeated use |

| Gas Dispersion Efficiency | Maximized, ensuring a uniform purification process |

How To Choose The Degassing Impeller ?

Type F Rotor Φ250×33

Due to the special design of its impeller grooves and outer peripheral teeth, Type F forms tiny bubbles. Its larger impeller size enhances dispersion in molten aluminum, while the thinner impeller minimizes surface fluctuations of the melt.

Application: Suitable for large flat ingot and round bar melting lines (double - rotor or triple - rotor degassing systems).

Type B Rotor Φ200×30

The impeller structure of Type B generates sufficient pressure to create small, uniform bubbles while reducing thermal shock.

Application: Suitable for continuous casting and rolling melting lines (single - rotor degassing systems).

Type D Rotor Φ200×60

Type D features a double - layer bread - shaped wheel design, enabling excellent agitation and diffusion of bubbles.

Application: Suitable for high - flow melting lines (double - rotor degassing equipment).

Type A

Type C

Silicon Nitride Ceramic Materials Obvious Advantages

Long service life and low maintenance costs

Due to the high - temperature strength, strong thermal shock resistance, and good corrosion resistance of silicon nitride ceramics, their service life generally reaches more than one year, thus reducing the replacement and maintenance costs.

No pollution to molten aluminum

Silicon nitride has low wettability to molten metals and hardly reacts with molten aluminum. Therefore, it will not cause secondary pollution to molten aluminum, which is of great help for stabilizing the quality of cast products.

Easier installation and maintenance

Silicon nitride ceramics can maintain a flexural strength of more than 500MPa and good thermal shock resistance below 800℃. Thus, the wall thickness of the product can be made thinner. In addition, due to its low wettability to molten metals, there is no need to apply a surface coating, which also makes the installation and maintenance of the devices easier.

Comparison Table of Cost-Performance of Common Immersion Materials in Aluminum Processing Industry

| Category | Index | Silicon Nitride | Cast Iron | Graphite | Reaction-Sintered SiC | Carbon-Nitrogen Bonded | Aluminum Titanate |

|---|---|---|---|---|---|---|---|

| Heater Protection Tube | Lifetime Ratio | >10 | — | — | 3–4 | 1 | — |

| Price Ratio | >10 | — | — | 3 | 1 | — | |

| Cost-Performance | High | — | — | Medium | Low | — | |

| Lifting Tube | Lifetime Ratio | >10 | 1 | — | — | 2 | 4 |

| Price Ratio | 10–12 | 1 | — | — | 2 | 4–6 | |

| Cost-Performance | High | Low | — | — | Medium | Medium | |

| Degassing Rotor | Lifetime Ratio | >10 | — | 1 | — | — | — |

| Price Ratio | 10–12 | — | 1 | — | — | — | |

| Cost-Performance | High | — | Medium | — | — | — | |

| Sealing Tube | Lifetime Ratio | >10 | 1 | — | — | — | 4–5 |

| Price Ratio | >10 | 1 | — | — | — | 6–7 | |

| Cost-Performance | High | Low | — | — | — | Medium | |

| Thermocouple Protection Tube | Lifetime Ratio | >12 | — | — | 2–4 | 1 | — |

| Price Ratio | 7–9 | — | — | 3 | 1 | — | |

| Cost-Performance | High | — | — | Medium | Low | — |

Customer Site

Factory Certifications

Trusted by Global Leaders – Used in 20+ countries