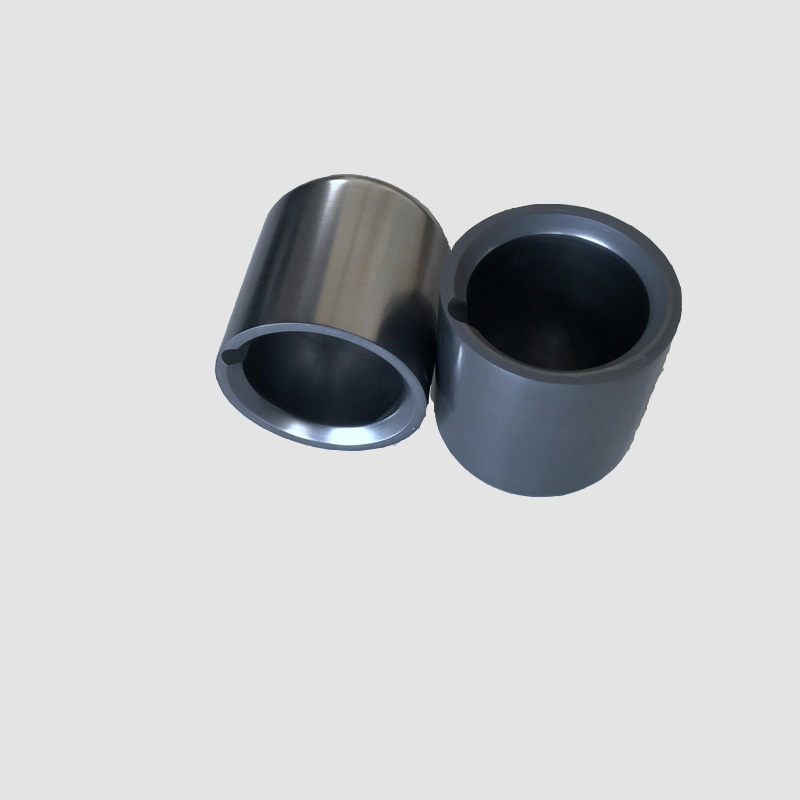

Graphite casting crucibles and stoppers

Features

Precious metal smelting is classified to primary smelting and refining. Refinery means getting high purity precious metal through smelting low purity metals, where graphite crucibles are needed with high purity, high bulk density, low porosity and good strength.

Graphite accessories for experimental equipment are made of high-quality, high-strength, high-purity, and high-density graphite, with a smooth surface and no pores. They have the characteristics of uniform thermal conductivity, rapid heating, high temperature resistance, and acid alkali corrosion resistance; In addition, special coating treatment can be used. After surface treatment, under long-term high-temperature heating, there will be no phenomenon of powder shedding, threshing, damage, and oxidation. It can withstand strong acids and alkalis, is durable, beautiful, and does not rust.

| Product Name | Diameter | Height |

| Graphite crucible BF1 | 70 | 128 |

| Graphite stopper BF1 | 22.5 | 152 |

| Graphite crucible BF2 | 70 | 128 |

| Graphite stopper BF2 | 16 | 145.5 |

| Graphite crucible BF3 | 74 | 106 |

| Graphite stopper BF3 | 13.5 | 163 |

| Graphite crucible BF4 | 78 | 120 |

| Graphite stopper BF4 | 12 | 180 |

When can I get the price?

We usually provide a quotation within 24 hours after receiving your detailed requirements, such as size, quantity, etc.

If it is an urgent order, you can call us directly.

Do you provide samples?

Yes, there are samples available for you to check our quality.

The sample delivery time is approximately 3-10 days.

What is the delivery cycle for mass production?

The delivery cycle is based on quantity and is approximately 7-12 days. For graphite products, it takes approximately 15-20 working days to obtain a dual-use item license.