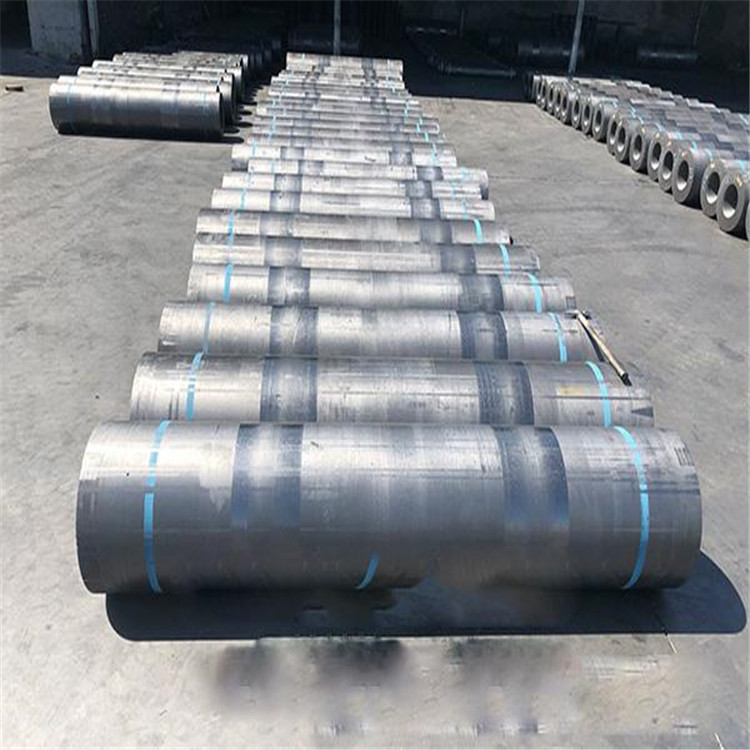

Graphite Electrodes

Features

Graphite electrodes are used in the electric smelting industry and have properties such as superconductivity, thermal conductivity, high mechanical strength, oxidation resistance, and high-temperature corrosion resistance.

Our graphite electrodes have low resistance, high density, high oxidation resistance, and precise machining accuracy, especially low sulfur and low ash, which will not bring secondary impurities to the steel.

Graphite has good chemical stability. Specially treated graphite has the characteristics of corrosion resistance, good thermal conductivity, and low permeability.

The graphite electrode raw material adopts low sulfur and low ash CPC. Add 30% needle coke to the HP grade electrode of the coking plant asphalt. UHP grade graphite electrodes use 100% needle coke and are widely used in LF. Steel making induction furnace, non-ferrous metal induction furnace. Silicon and phosphorus industries.

| UHP Size and Tolerance | ||||||||||||

| Diameter (mm) | Length (mm) | |||||||||||

| Nominal diameter | Actual diameter | Nominal length | Tolerance | Short feet length | ||||||||

| mm | inch | max | min | mm | mm | max | min | |||||

| 200 | 8 | 209 | 203 | 1800/2000/ 2200/2300 2400/2700 |

±100 | -100 | -275 | |||||

| 250 | 10 | 258 | 252 | |||||||||

| 300 | 12 | 307 | 302 | |||||||||

| 350 | 14 | 357 | 352 | |||||||||

| 400 | 16 | 409 | 403 | |||||||||

| 450 | 18 | 460 | 454 | |||||||||

| 500 | 20 | 511 | 505 | |||||||||

| 550 | 22 | 556 | 553 | |||||||||

| 600 | 24 | 613 | 607 | |||||||||

| Physical and Chemical Index of UHP | ||||||||||||

| Items | unit | Diameter: 300-600mm | ||||||||||

| Standard | Test data | |||||||||||

| Electrode | Nipple | Electrode | Nipple | |||||||||

| Electrical resistance | μQm | 5.5-6.0 | 5.0 | 5.0-5.8 | 4.5 | |||||||

| Flexure strength | Mpa | 10.5 | 16 | 14-16 | 18-20 | |||||||

| Modulus of elasticity | GPa | 14 | 18 | 12 | 14 | |||||||

| Ash content | % | 0.2 | 0.2 | 0.2 | 0.2 | |||||||

| Apparent density | g/cm3 | 1.64-16.5 | 1.70-1.72 | 1.72-1.75 | 1.78 | |||||||

| Factor of expansion(100-600℃) | x10-6/°℃ | 1.5 | 1.4 | 1.3 | 1.2 | |||||||

Q: How about the packing?

1. Standard export cardboard boxes/plywood boxes

2. Customized shipping marks

3. If the packaging method is not safe enough, the QC department will conduct an inspection