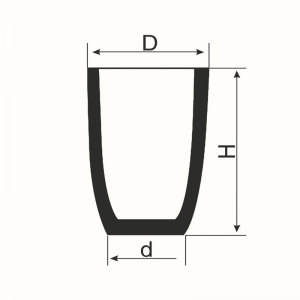

Induction heating crucible

Features

In modern metalworking and recycling industries, induction heating has become the preferred method for efficient and precise melting processes. The choice of crucible plays a critical role in ensuring that these processes run smoothly, especially in induction furnaces. We have developed Induction Heating Crucibles using isostatic pressing technology to provide unmatched performance in these demanding applications.

Unlike standard crucibles, which may struggle with the magnetic fields in induction furnaces, our crucibles are designed to generate heat through magnetic induction. This innovation not only enhances energy efficiency but also extends the lifespan of the crucible, making it the ideal choice for industries such as aluminum recycling and metal casting.

Key Features of Induction Heating Crucibles

Our Induction Heating Crucibles stand out due to their unique combination of materials and manufacturing processes. Here’s why they are the top choice for induction furnace users:

| Feature | Benefit |

|---|---|

| Isostatic Pressing Technology | Ensures uniform density for enhanced durability and mechanical strength |

| Magnetic Heating Properties | Designed to generate heat through magnetic induction, improving efficiency |

| Thermal Conductivity | Faster heat transfer for reduced melting time and energy consumption |

| Corrosion Resistance | Superior resistance in harsh environments, particularly in aluminum recycling |

| Extended Lifespan | Lasts over one year, surpassing the performance of European competitors |

The magnetic properties of these crucibles are particularly important for users of induction furnaces, where the ability to conduct heat through induction can dramatically increase the overall efficiency of the process. This not only saves time but also reduces energy costs, making it a cost-effective solution for businesses.

Applications of Induction Heating Crucibles

- Aluminum Recycling Industry:

- In the recycled aluminum industry, corrosion resistance is critical due to the harsh conditions involved in the process. Our crucibles are specially designed to handle these environments, offering a lifespan that exceeds European crucibles by more than 20%.

- The high thermal conductivity ensures faster melting times, which boosts productivity and reduces energy consumption.

- Induction Furnaces:

- Traditional crucibles often lack magnetic properties, which can result in inefficiencies when used in induction furnaces. Our induction heating crucibles are engineered with magnetic heating capabilities, meaning the crucible itself generates heat, improving overall process efficiency and further reducing energy costs.

- With a lifespan of over one year, these crucibles significantly outlast their counterparts, reducing downtime and replacement costs.

- Other Metal Melting Applications:

- Whether for copper, zinc, or silver melting processes, our crucibles provide reliable performance, ensuring consistent results across various industries.

Maintenance and Usage Tips for Induction Heating Crucibles

To maximize the lifespan and efficiency of your Induction Heating Crucible, it’s important to follow proper usage and maintenance practices:

- Preheating: Gradually heat the crucible to the desired temperature to avoid thermal shock.

- Cleaning: Regularly clean the crucible to remove residues that could impact performance and shorten the lifespan.

- Storage: Store crucibles in a dry, cool environment to prevent exposure to moisture or corrosive elements that could degrade the material over time.

These practices will help ensure that your crucible operates at peak efficiency for longer, reducing the frequency of replacements and maintenance.

Product Promotion

We are proud to offer Induction Heating Crucibles designed for maximum durability and performance. Our crucibles feature isostatic pressing technology, which ensures uniformity and strength, making them more resistant to thermal shock and mechanical stress. With the ability to generate heat through magnetic induction, our crucibles are tailored specifically for induction furnace applications, where precision and energy efficiency are paramount.

Customization Options: We understand that every industry has unique requirements. That’s why we offer fully customizable crucibles, tailored to meet your specific operational needs. Whether you need a different shape, size, or composition, our team is ready to work with you to create the perfect solution.

Technical Support: Our dedicated team provides full technical support to help you get the most out of your crucibles. From initial installation to ongoing maintenance advice, we are here to ensure that your processes run smoothly and efficiently.

Call to Action

If you are looking to enhance the efficiency of your induction heating processes, our Induction Heating Crucibles are the perfect solution. With isostatic pressing technology, superior magnetic heating properties, and an extended lifespan, these crucibles offer the reliability and performance your business needs to stay ahead in a competitive market.

Contact us today to learn more about our customized crucible solutions and how they can improve your production processes.