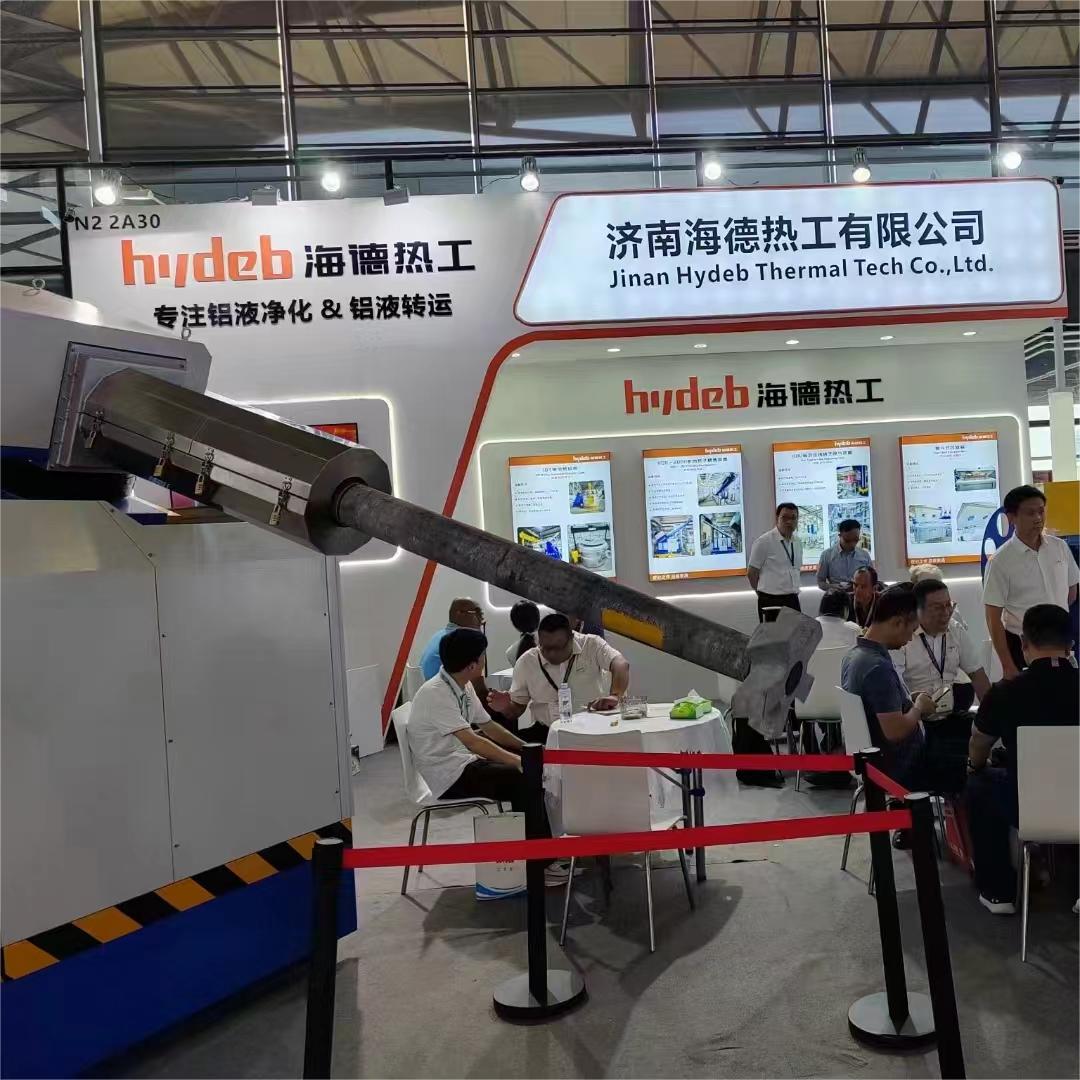

Our company is proud to announce the launch of our newest product - the high performance "Graphite Rotor". This innovative product is designed to improve the efficiency and quality of the casting process and marks a major technological breakthrough for the foundry industry.

Background and R&D purpose

In the foundry industry, the uniformity and cleanliness of molten metal are key factors in ensuring the quality of the final product. Traditional metal rotors often have problems with poor corrosion resistance and short life when stirring molten metal. In order to solve these problems that have long plagued foundry companies, our company invested a lot of resources in research and development, and finally launched this high-performance "graphite rotor".

Features

Excellent corrosion resistance: Graphite materials have excellent chemical corrosion resistance, especially in high-temperature molten metal environments. This feature significantly extends the service life of the rotor and reduces the cost of frequent replacement.

Efficient stirring performance: The unique design of the graphite rotor ensures uniform stirring of the molten metal, improves the uniformity of the metal, reduces the formation of bubbles and inclusions, thereby improving the quality of castings.

Stable thermal performance: The graphite rotor has good thermal conductivity and stability, maintaining its physical and chemical properties in high temperature environments, ensuring the stability and consistency of the mixing process.

manufacturing process

Our company uses advanced isostatic pressing technology to manufacture graphite rotors. This process ensures uniform density and strength of the graphite rotor, thereby improving its overall performance and durability.

Market Outlook

The launch of graphite rotors has attracted widespread attention and praise in the industry. Industry experts pointed out that the launch of this product is expected to trigger technological revolutions in multiple application fields, especially in high-demand casting fields such as aluminum alloys and copper alloys. The advantages of graphite rotors are particularly significant.

customer feedback

Our company's first batch of graphite rotors have been tested in many large casting companies. Customer feedback shows that the use of graphite rotors not only improves production efficiency, but also significantly reduces production costs. The technical director of a well-known foundry company said: "Our company's graphite rotor has greatly improved our production stability and product quality. We are very satisfied with its performance."

prospect

Our company is committed to continuously promoting technological progress in the foundry industry. In the future, the company will continue to increase investment in research and development, introduce more high-performance, high-quality casting equipment and materials to meet market demand and help customers achieve more efficient and environmentally friendly production goals.

Our company welcomes new and old customers to inquire and cooperate with us to jointly promote the vigorous development of the foundry industry.

This press release once again demonstrates our company's leading position and technological innovation capabilities in the field of casting equipment. As an industry leader, our company will continue to adhere to the business philosophy of "quality first, customer first" to provide customers with the highest quality products and services.

Post time: Jul-23-2024