-

How long is the lifespan of graphite crucibles used for metal smelting?

In metal smelting and other high-temperature applications, Graphite Carbon Crucible are indispensable tools. They are used to heat metals to extremely high temperatures for casting, melting, and other processing operations. However, the common ...Read more -

How to make a graphite crucible: from raw materials to finished products

Graphite Carbon Crucible are commonly used tools in metal smelting, laboratory applications, and other high-temperature treatment processes. They have excellent high-temperature stability and thermal conductivity, making them very ...Read more -

How to Temper Graphite Crucibles: Improving Performance and Extending Service Life

Crucible For Smelting play a crucial role in metal smelting, laboratory applications, and other high-temperature processes, and are highly praised for their high-temperature stability and thermal conductivity. However, over time, the surface of...Read more -

How to Clean Graphite Crucibles: Key Steps to Extend Service Life

Graphite Crucible are widely used tools in metal smelting and high-temperature applications. They are used to heat metals or other substances to high temperatures for melting, casting, and other high-temperature processing. However, over time, ...Read more -

Common problems and analysis of crucibles: deciphering puzzles in materials science

In modern industry and scientific research, crucibles play an important role in melting metals, chemical experiments, and many other applications. However, Crucible For Melting often encounter various problems during use, such as transverse cracks, longitudinal cracks, a...Read more -

Decoding the Melting Point of High Purity Clay Graphite Crucible

High temperature metal smelting is a key link in the manufacturing industry, from automotive parts to electronic products to space probes, all require the use of high-temperature furnaces to melt and process various metal materials. In this complex process, Graphite Clay...Read more -

How to Manufacture Silicon Carbide Crucibles: A Crucible Adventure!

Silicon Carbide Graphite Crucible, they sound like magical tools of a mysterious wizard, but in reality, they are true superheroes in the industrial world. These little guys are used to melt various metals and are an essential part...Read more -

Domestic graphite crucibles surpass imported ones: groundbreaking performance in harsh environments

In recent years, the production technology of domestic graphite crucibles has made significant progress. Not only have they caught up with imported crucibles, but in some cases even exceeded them. By employing innovative manufactur...Read more -

The characteristics of our graphite electrode

The characteristics of our graphite electrode: 1. Stable and reasonable prices: The price of graphite material only requires 15% of the same volume of copper electrode. Currently, graphite has become a popular material for EDM applications, wit...Read more -

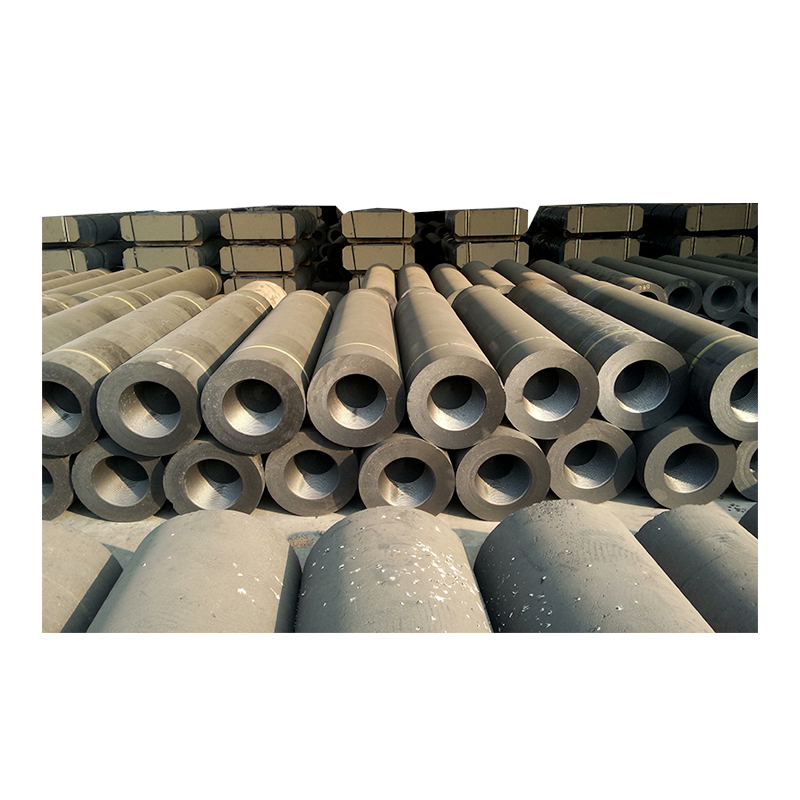

Graphite rotor for aluminum casting

Product Introduction: The working principle of a graphite rotor is that the rotating rotor breaks the nitrogen (or argon) blown into the aluminum melt into a large number of dispersed bubbles and disperse...Read more -

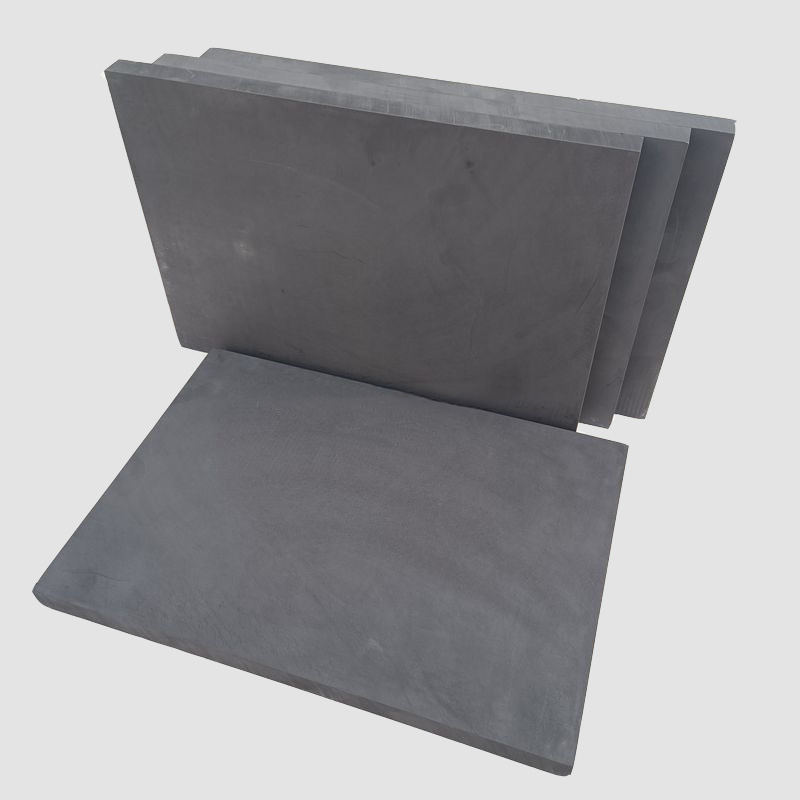

Developing a new generation of high-purity graphite materials

High purity graphite refers to graphite with a carbon content greater than 99.99%. High purity graphite has advantages such as high temperature resistance, corrosion resistance, thermal shock resistance, low therma...Read more -

Detailed Explanation of Isostatic Pressing Graphite (2)

1.4 Secondary grinding The paste is crushed, ground, and sieved into particles of tens to hundreds of micrometers in size before being mixed evenly. It is used as a pressing material, called pressing powder. The equipment for secon...Read more