-

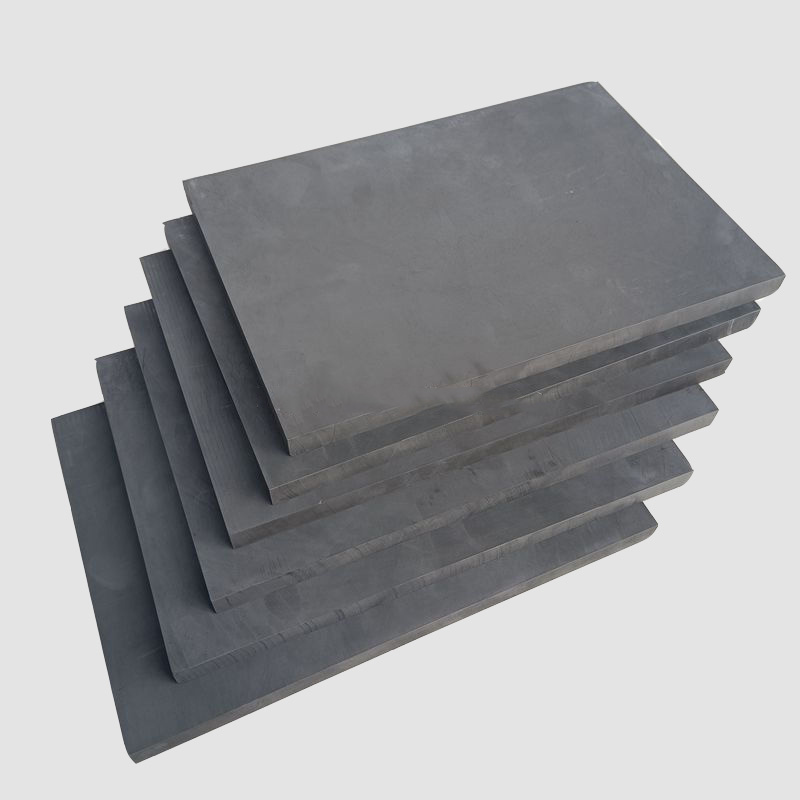

Detailed Explanation of Isostatic Pressing Graphite (1)

Isostatic pressing graphite is a new type of graphite material developed in the 1960s, which has a series of excellent properties. For example, isostatic pressing graphite has good heat resistance. In an inert atmosphere, its mecha...Read more -

Detailed Explanation of the Uses of Graphite Products

The use of graphite products is much higher than we expected, so what are the uses of graphite products that we are currently familiar with? 1、 Used as a conductive material When smelting various alloy steels, ferroalloys, or producing calcium...Read more -

Advantages, Disadvantages, and Applications of Graphite Materials

Graphite is an allotrope of carbon, which is a gray black, opaque solid with stable chemical properties and corrosion resistance. It is not easily reactive with acids, alkalis, and other chemicals, and has advantages such as high temperature re...Read more -

Common problems and analysis of crucibles (2)

Problem 1: Holes and Gaps 1.The appearance of large holes on the walls of the crucible that have not yet thinned is mostly caused by heavy blows, such as throwing ingots into the crucible or blunt impact when cleaning up residue 2.Small holes a...Read more -

Overview The Graphite Crucible

Overview The graphite crucible is made from natural flake graphite as the main raw material, and is processed with plastic refractory clay or carbon as the binder. It has the characteristics of high temperature resistance, strong thermal conduc...Read more -

Method of use for silicon carbide graphite crucibles

Graphite crucible Silicon carbide graphite crucible is a container made of graphite as raw material, so it has excellent high temperature resistance and can be used in industrial metal smelting or casting. For example, in daily life, you can un...Read more -

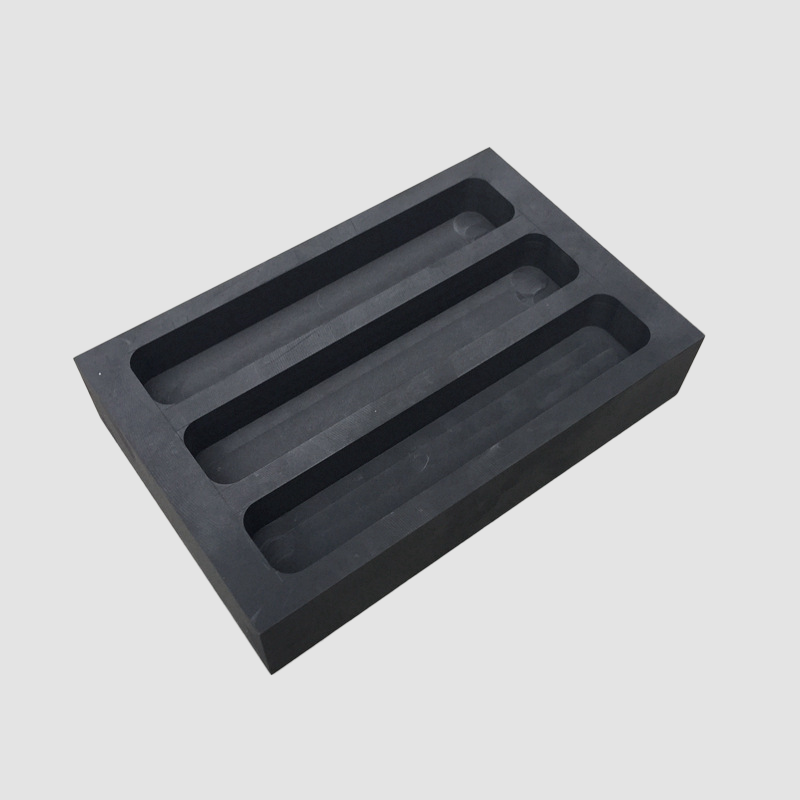

Introduce of Graphite Crucibles

Graphite crucibles have good thermal conductivity and high temperature resistance. During high-temperature use, their coefficient of thermal expansion is small, and they have certain strain resistance for rapid heating and cooling. Strong corro...Read more -

Deslagging and emptying graphite crucibles

1. Slag removal of graphite crucible Wrong approach: residual additives in the crucible will penetrate the crucible wall and corrode the crucible, thus shortening the life of the crucible. Correct method: You must use a steel shovel with a flat bottom every day to care...Read more -

Advantages of Graphite Crucibles: Essential Components in Metallurgy and Chemical Industries

In various industries, there exists a widespread misconception regarding the utility of graphite crucible. Many individuals mistakenly believe that these products have minimal significance in the market, assuming them to be unimportant. However...Read more -

The Ultimate Silicon Carbide Casting Crucible: Benefits and Features Revealed

Welcome to our blog where we discuss the salient benefits and features of our flexible, crack resistant, durable SiC Graphite crucibles. Our crucibles are a game changer in the foundry industry with their massive production capacity, increasing yield, ensuring quality, r...Read more -

High-Temperature Applications Made Safer with Graphite Crucibles: Tips for Proper Usage and Installation

Graphite crucibles are renowned for their exceptional heat conductivity and high-temperature resistance. Their low coefficient of thermal expansion grants them resilience against rapid heating and cooling, making them suitable for demanding app...Read more -

Carbonized Silicon Graphite Crucible Usage Guidelines

In order to ensure the proper and efficient use of carbonized silicon graphite crucibles, the following guidelines should be strictly adhered to: Crucible Specification: The capacity of the crucible should be designated in kilograms (#/kg). Moi...Read more