The aluminium scrap melting recycling industry is booming, and choosing the right aluminum scrap melting furnace is crucial to improving efficiency and reducing costs. This article will compare and analyze the two common aluminum scrap melting furnace - the reverberatory furnace and the crucible furnace, and introduce our advanced vortex melting technology to help you make an informed choice based on your needs.

Advantages:

The reflector furnace has a large capacity and can handle a large amount of aluminium scrap melting at one time, which is suitable for large-scale production. Can handle all types and shapes of scrap aluminum, including thin materials, chips, etc. The structure is relatively simple, and the operation and maintenance are convenient.

Cons:

The thermal efficiency of the reflector furnace is low, the energy consumption is high, and the operation cost is relatively high. In the smelting process, the metal burn rate is high, and the aluminium scrap melting recovery rate is reduced. Combustion exhaust emissions are large, need to be equipped with perfect environmental protection facilities.

Advantages: simple equipment structure, low investment cost, suitable for small processing plants. It can be started and stopped at any time, suitable for small batch and multi-variety production. It can be used for smelting aluminum alloy, magnesium alloy and other special alloys.

Cons:

Small capacity, low production efficiency. Low thermal efficiency, high energy consumption, high operating costs. Need manual operation, labor intensity is relatively large.

3. Vortex melting technology in our factory

In view of the problems of large metal burning loss and low recovery rate in the traditional aluminum scrap melting furnace, our factory has developed advanced vortex melting technology. Through the unique swirl design, the thin scrap aluminum material is heated more evenly during the smelting process, which significantly reduces the heat loss and improves the metal recovery rate.

Advantages of vortex melting technology:

The unique swirl design makes the thin scrap aluminum material heat evenly and reduces the heat burn loss. The reduction of heat burn loss directly improves the metal recovery rate and creates greater economic benefits for customers. This technology has been widely used in various aluminum can melting furnace and has been well received by customers.

Different types of aluminium scrap melting furnace have their own advantages and disadvantages, and the selection of the appropriate furnace type needs to consider the production scale, raw material type and investment budget.

· Large-scale production and treatment of various types of waste aluminum: reflex furnace is a more suitable choice.

· Small batch production, limited investment budget: crucible furnace can meet the basic needs.

· In pursuit of energy efficiency and improved metal recovery: our vortex melting technology is the ideal choice.

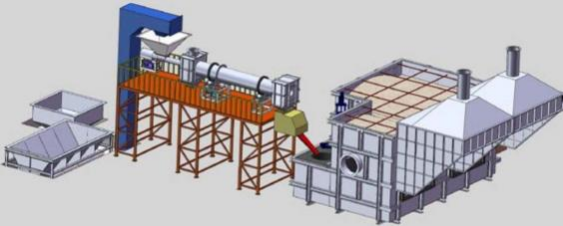

In view of the melting problem of thin and light crushing scrap material, combined with foreign advanced technology experience, it is particularly important to develop the corresponding pretreatment line equipment and special a scrap melting furnace type. Thin and light crushing material pre-treatment line equipment includes pressing, crushing, iron removal, paint removal, granulation, deoiling, eddy current decontamination, drying, feeding and conveying links, usually adopt mechanical automatic uniform conveying equipment, instead of manual feeding.

scrap aluminum melting furnace type is usually selected two-chamber furnace, the rear wall of the furnace is configured with a side pool, and the side pool is installed with aluminum water circulation mechanical pump, and the thin crushing material is melted through the aluminum water vortex, so as to completely solve the problems of high energy consumption, large burning loss and serious pollution when the thin crushing material is melted. The two-chamber side-pond scrap aluminum melting furnace has the advantages of low oxidation burning loss, high aluminum water recovery rate, less slag production, good environmental protection effect, high melting efficiency, low energy consumption, mechanized continuous feeding melting, etc., which is currently recognized as the most mature technology suitable for online recovery of thin and light crushing materials.

Post time: Mar-12-2025