With the continuous advancement of aluminum smelting technology, silicon carbide graphite crucible has gradually become a star product in the aluminum manufacturing industry due to its excellent performance and reliability. These crucibles not only meet the strict requirements of high-temperature smelting, but also have significant energy efficiency and environmental friendliness, making them key equipment for the development of the modern aluminum industry.

Unique advantages of silicon carbide graphite crucible

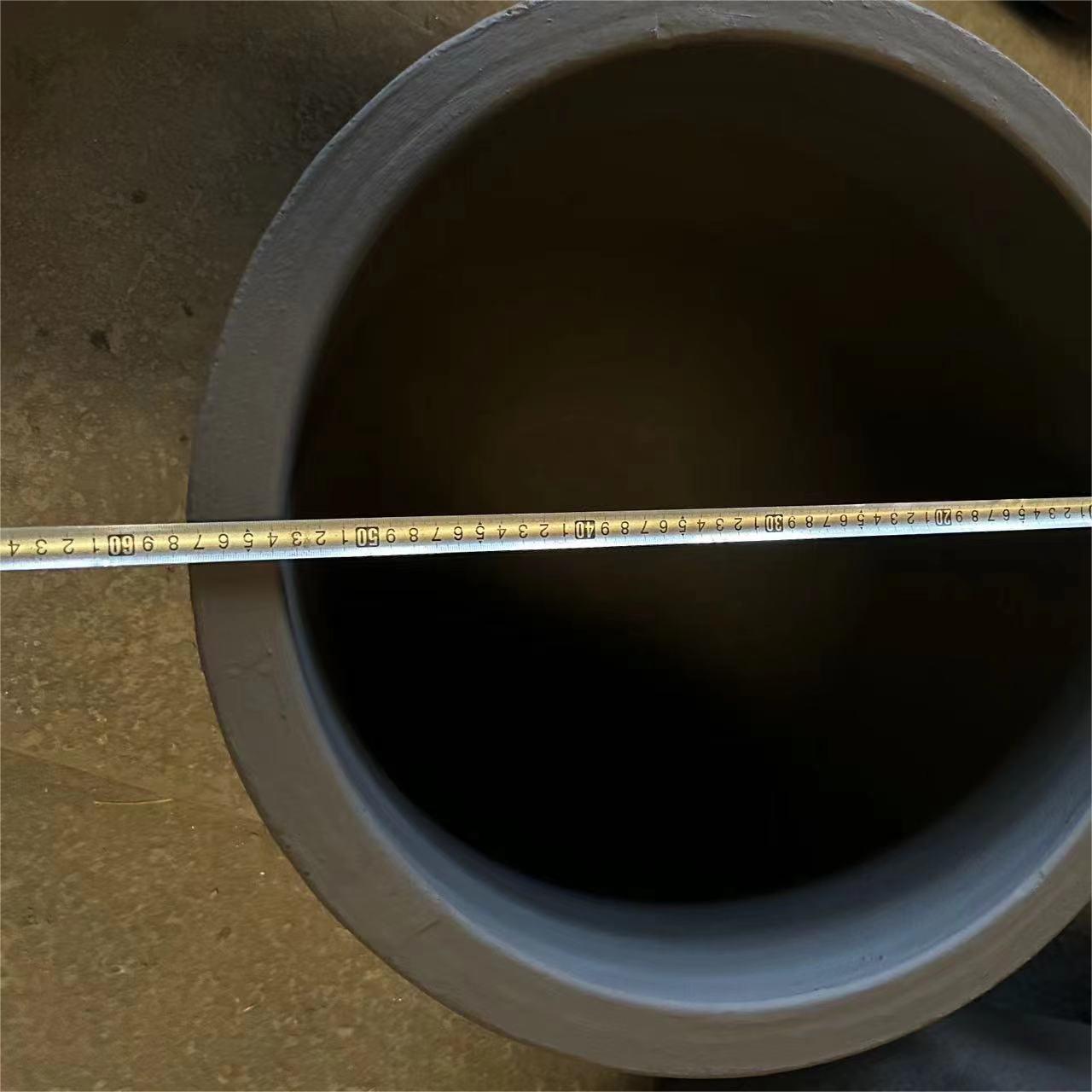

Silicon carbide graphite crucible is a refractory crucible made of a mixture of silicon carbide and graphite, specially used in the smelting process of aluminum and its alloys. The unique material composition gives the crucible a variety of excellent properties:

Excellent thermal conductivity: Both silicon carbide and graphite have high thermal conductivity, which can achieve rapid and uniform heat transfer, improve smelting efficiency, reduce smelting time, and minimize energy consumption.

High temperature oxidation resistance: The combination of silicon carbide and graphite gives the crucible excellent oxidation resistance at high temperatures, effectively preventing surface oxidation and extending its service life.

Superior mechanical strength: Silicon carbide graphite crucible maintains high mechanical strength even at high temperatures, allowing it to withstand the thermal and mechanical stress generated during aluminum smelting, thereby reducing the risk of damage.

Chemical corrosion resistance: Silicon carbide and graphite materials have good chemical corrosion resistance to aluminum and its alloys, further extending the service life of the crucible and maintaining the purity of the smelting product.

Technological innovation drives crucible manufacturing

The advancement of modern manufacturing technology has continuously improved the production process of silicon carbide graphite crucibles. For example, precise material mixing and advanced sintering technology enable manufacturers to produce crucibles with dense structures and stable performance. In addition, the introduction of 3D printing technology makes it possible to design complex-shaped crucibles to meet the specific requirements of various aluminum smelting processes.

Contribute to environmental protection and sustainable development

In addition to superior performance, silicon carbide graphite crucibles also actively contribute to environmental protection and sustainable development. Efficient heat conduction reduces energy consumption, while the durability of the crucible reduces the frequency of replacement, thereby minimizing the generation of industrial waste. Some manufacturers are also exploring the use of recycled materials to further reduce environmental impact.

Market prospects and applications

As the aluminum industry continues to develop, the demand for high-performance smelting equipment is increasing. Silicon carbide graphite crucibles are increasingly favored by the market for their excellent performance and environmental protection characteristics. Whether in aluminum foundries or aluminum processing companies in the automotive, aerospace and other industries, silicon carbide graphite crucibles have become a reliable choice to improve production efficiency and product quality.

in conclusion

The emergence of silicon carbide graphite crucible marks that aluminum smelting technology has entered a new era. As an innovator in aluminum smelting equipment, silicon carbide graphite crucibles not only improve production efficiency and product quality, but also set industry benchmarks in energy efficiency and environmental protection. We will continue to be committed to the R&D and production of higher-performance silicon carbide graphite crucibles, provide customers with reliable smelting solutions, and promote the sustainable development of the aluminum industry.

Post time: May-31-2024