From the jewelry we wear to the cars we drive, metal is everywhere in our daily lives. But have you ever wondered how these metals went from raw ores to the products we depend on for our survival? The answer lies in smelting furnaces - these industrial behemoths that combine heat and the mighty power of chemical reactions to unlock the true potential of metals.

Smelting Furnaces: Not Just Heat

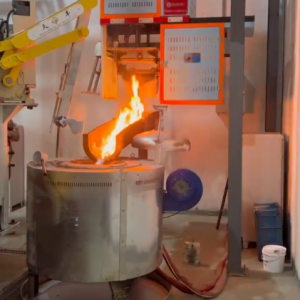

While the term "furnace for smelting" may conjure up images of a simple heating device, modern melting furnaces are complex engineering marvels. They are carefully designed to withstand extreme temperatures, often in excess of thousands of degrees Celsius, and to control the atmosphere to promote specific chemical reactions.

Depending on the metal and the desired result, there are many types of smelting furnaces:

- Blast furnaces: These furnace melters are the backbone of iron production, using coke (a fuel made from coal) to reduce iron ore to pig iron.

- Electric Arc furnaces: These melting furnaces use a powerful electric arc to melt scrap steel, making them ideal for steel recycling.

- Induction furnaces: These furnaces for smelting use electromagnetic induction to heat and melt metals, providing precise temperature control and minimal contamination.

- Reverberatory furnaces: These smelting furnaces are traditionally used to melt non-ferrous metals such as copper, using the heat generated by fuel combustion to melt the metal.

Beyond Smelting: The Versatility of Furnaces

Although smelting is the main function of furnace melters, they also play a vital role in other metal processing processes:

- Melting: Before casting, the metal is heated above its melting point in a melting furnace.

- Refining: Removes impurities from metals to improve their quality and performance using a furnace for smelting.

- Alloying: Combining different metals to create new materials with specific properties in a smelting furnace.

Smelting Furnace Competition: Reverberatory, Induction, and Crucible Furnaces – Who is Your Best Choice?

In the world of metal processing, choosing the right furnace melter is like choosing a weapon in hand, which is directly related to production efficiency and product quality. Faced with a wide variety of melting furnaces, are you dazzled? Don’t worry, this article will give you a detailed introduction to three common smelting furnaces: reverberatory, induction, and crucible furnaces, and analyze their advantages and disadvantages to help you make an informed choice.

1. Reverberatory Furnace: Stick to the Traditional Technology

Working Principle: The reverberatory furnace for smelting uses the heat generated by the combustion of fuel to reflect through the furnace top to the furnace to heat and melt the metal.

Advantages:

- Simple structure, easy operation: The reverberatory melting furnace structure is relatively simple, easy to operate and maintain, suitable for small foundry use.

- Low investment cost: Compared with other types of smelting furnaces, the investment cost of the reverberatory furnace is lower, suitable for users with limited budgets.

- Suitable for a variety of metals: The reverberatory furnace melter can be used to melt a variety of metals, including copper, aluminum, zinc, etc.

Disadvantages:

- Low thermal efficiency, high energy consumption: The thermal efficiency of the reverberatory furnace for smelting is relatively low, the fuel consumption is large, and the operating cost is high.

- Serious environmental pollution: The combustion process of the reverberatory melting furnace will produce a lot of smoke and waste gas, causing pollution to the environment.

- Low temperature control accuracy: The temperature control accuracy of the reverberatory smelting furnace is low, and it is difficult to meet some process requirements for strict temperature requirements.

2. Induction Furnace: The Modern Choice of High Efficiency and Energy Saving

Working Principle: The induction furnace melter uses the principle of electromagnetic induction to generate eddy currents inside the metal, thereby generating heat to melt the metal.

Advantages:

- Heating speed, high efficiency: The induction melting furnace heating speed is very fast, with high thermal efficiency, which can significantly shorten the melting time and improve production efficiency.

- Precise temperature control: The temperature control precision of the induction furnace for smelting is high, which can meet the needs of various precision casting processes.

- Small environmental pollution: The induction smelting furnace uses electric energy as an energy source, does not produce smoke and waste gas, and is environmentally friendly.

Disadvantages:

- High investment cost: The equipment investment cost of the induction furnace melter is high, which is suitable for large-scale foundry.

- Sensitive to metal composition: The induction melting furnace is more sensitive to metal composition, and different components of metal require different process parameters.

- Electromagnetic interference: The induction furnace for smelting will produce electromagnetic interference when working, and corresponding protective measures need to be taken.

3. Crucible Furnace: Flexible Small Smelting Experts

Working Principle: The crucible smelting furnace puts the metal into a high-temperature resistant crucible and heats the crucible through an external heat source, thereby indirectly heating and melting the metal.

Advantages:

- Strong flexibility: The crucible furnace melter is small in size, easy to move, and can flexibly adjust the production position according to needs.

- Suitable for small batch production: The crucible melting furnace is suitable for small batch and multi-variety metal smelting, such as precious metals, special alloys, etc.

- Low investment cost: The investment cost of crucible smelting furnaces is relatively low, suitable for small foundries and laboratories.

Disadvantages:

- Slow melting speed: The melting speed of the crucible furnace for smelting is relatively slow, and the production efficiency is low.

- Limited crucible life: The crucible in the furnace melter needs to be replaced regularly, increasing the operating cost.

- Low temperature control accuracy: The temperature control accuracy of the crucible melting furnace is low, and it is difficult to meet some process requirements for strict temperature requirements.

The Future of Smelting Furnaces: Innovation and Sustainability

As the world's demand for metals continues to grow, the smelting furnace industry is constantly innovating to improve efficiency, reduce emissions, and minimize environmental impact. Some promising developments include:

- Use renewable energy: Explore the use of clean energy sources such as solar and hydrogen to power furnaces for smelting.

- Carbon capture and storage: Develop technologies to capture and store carbon dioxide emissions released during the melting furnace process.

- Advanced automation: Implement artificial intelligence and machine learning to optimize the furnace melter process and reduce energy consumption.

Choose Us, Choose Success

We are committed to providing customers with the best quality smelting furnace solutions, helping you improve production efficiency, reduce production costs, and improve product quality. We offer various types of melting furnaces, including reverberatory, induction, and crucible furnaces, and can customize them to meet your specific needs.

Our Advantages:

- One-stop solution: From design to delivery, we provide a full range of services for furnaces for smelting, saving you time and effort.

- Extensive experience: We have many years of experience in the smelting furnace industry, successfully serving many customers.

- Advanced technology: We continue to introduce and develop advanced melting furnace technology to ensure our products are efficient, energy-saving, and environmentally friendly.

- Professional team: We have an experienced and skilled team of engineers to provide you with professional technical support and service for furnace melters.

- Perfect after-sales service: We provide a perfect after-sales service system, including equipment maintenance, spare parts supply, and technical consultation for smelting furnaces, to solve your worries.

If you are looking for a reliable furnace for smelting partner, please contact us today. We will be happy to serve you!

Post time: Mar-23-2025