There are significant differences between silicon carbide crucibles and graphite crucibles in many aspects such as materials, processes, performance, and prices. These differences not only affect its manufacturing process, but also determine its effectiveness and application scenarios.

substantial difference

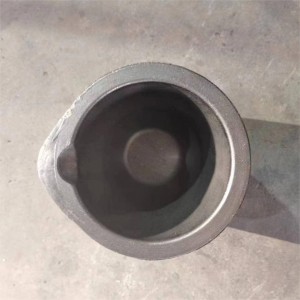

Graphite crucibles are mainly made of natural flake graphite and use clay as a binder. This combination gives the graphite crucible excellent thermal conductivity and high temperature resistance, making it suitable for applications in high-temperature melting processes. The unique structure and high thermal conductivity of natural flake graphite make graphite crucibles very popular in the metallurgical and foundry industries.

Silicon carbide crucible is based on natural flake graphite, with silicon carbide as the main component and high-temperature resin as the binder. As a superhard material, silicon carbide has extremely high wear resistance and thermal stability, allowing silicon carbide crucibles to be used in more harsh environments. The use of high-temperature resin also enhances the crucible's overall strength and durability.

Process differences

The manufacturing process of graphite crucible mainly relies on manual and mechanical pressing. Small graphite crucibles are generally formed by mechanical pressing, then sintered in a kiln at a high temperature of 1,000 degrees, and finally coated with anti-corrosion glaze or moisture-proof paint to increase durability and corrosion resistance. This traditional process, while cost-effective, has limitations in terms of production efficiency and quality consistency.

The production process of silicon carbide crucible is relatively advanced, using isostatic pressing equipment and scientific formula. Isostatic pressing technology applies uniform pressure (up to 150 MPa), resulting in higher density and consistency in the crucible. This process not only improves the crucible's mechanical strength, but also significantly enhances its resistance to thermal shock and corrosion.

Performance differences

In terms of performance, there are significant differences between graphite crucibles and silicon carbide crucibles. Graphite crucibles have a density of 13 kA/cm², while silicon carbide crucibles have a density of 1.7 to 26 kA/mm². The service life of graphite crucibles is usually 3-5 times that of silicon carbide crucibles, which is mainly due to the superior material strength and corrosion resistance of silicon carbide crucibles.

In addition, the temperature difference between the inside and outside of the graphite crucible is about 35 degrees, while the temperature difference of the silicon carbide crucible is only 2-5 degrees, making the silicon carbide crucible more superior in terms of temperature control and thermal stability. The acid and alkali resistance and corrosion resistance of silicon carbide crucibles are also far higher than those of graphite crucibles, which significantly improves energy efficiency and saves about 50% energy than graphite crucibles.

difference in price

Due to differences in materials and manufacturing processes, graphite crucibles and silicon carbide crucibles also have significant price differences. Typically, silicon carbide crucibles are about three times more expensive than graphite crucibles. This price difference reflects the significant advantages of silicon carbide crucibles in terms of material cost, manufacturing process complexity and performance.

In summary, although silicon carbide crucibles cost more, their superior durability, corrosion resistance, and energy efficiency make them a more cost-effective choice for many demanding applications. Graphite crucibles remain widely used in many traditional applications due to their lower cost and good basic properties. The respective advantages and disadvantages of these two crucibles determine that they are suitable for different application scenarios.

Post time: Jun-13-2024