Introduction

Choosing the right crucible is essential for efficient metal melting and casting processes. Whether you’re working with silicon carbide crucibles or graphite crucibles, understanding their uses, temperature ranges, and key features can enhance productivity and performance. In this article, we’ll cover everything you need to know, from graphite crucible sizes to silicon carbide bonding, while answering questions like What is used to melt metal? and What temperature does silver melt?

Outline

1. What Are Silicon Carbide and Graphite Crucibles?

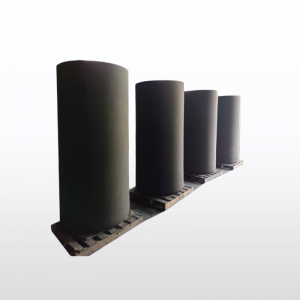

- Silicon Carbide Crucibles: Manufactured using high-quality silicon carbide with graphite bonding, these crucibles are known for their resistance to high temperatures, oxidation, and thermal shock.

- Graphite Crucibles: Made of pure graphite, these crucibles excel in high-temperature stability and are ideal for metals with higher melting points.

2. Key Features and Applications

- Temperature Ranges:

Crucible Type Temperature Range (°C) Silicon Carbide Up to 1650°C Graphite Up to 3000°C - Applications: Both types of crucibles are perfect for melting and refining non-ferrous metals like copper, silver, and gold. Commonly used in jewelry making, foundries, and continuous casting processes.

- Durability:

- Silicon carbide crucibles are thermal-shock-resistant and designed for frequent heating cycles.

- Graphite crucibles are chemically stable and can handle corrosive environments.

3. Graphite Crucible Sizes and Metal Compatibility

- Sizes:

Graphite crucibles are available in various sizes to suit small-scale to industrial applications.Size Capacity Small 1–5 kg Medium 6–20 kg Large 21 kg and above - Metal Compatibility:

Metal Type Melting Point (°C) Recommended Crucible Copper ~1085 Silicon Carbide or Graphite Silver ~961 Silicon Carbide or Graphite Gold ~1064 Graphite

4. Silicon Carbide and Graphite Crucible Uses

- Silicon Carbide Crucibles: Ideal for metals that require rapid heating cycles, such as in the continuous casting process.

- Graphite Crucibles: Preferred for high-temperature metals and as components in ladle furnaces, shroud manipulators, and tundish stoppers due to their excellent conductivity.

5. Maintenance and Care Tips

To maximize crucible lifespan and efficiency:

- Avoid Sudden Temperature Changes: Prevent cracks caused by thermal shock.

- Regular Cleaning: Remove slag and residues after each use.

- Proper Storage: Keep in a dry, moisture-free environment to avoid material degradation.

Common FAQs for Professional Buyers

- Q: What is used to melt metals like copper and silver?

A: Silicon carbide and graphite crucibles are commonly used due to their high melting points and excellent thermal stability. - Q: What is the melting temp of copper and graphite?

A: Copper melts at approximately 1085°C, while graphite crucibles can withstand temperatures up to 3000°C. - Q: Which crucible is best for industrial casting?

A: Graphite crucibles are preferred for high-temperature metals, while silicon carbide crucibles are ideal for fast heating cycles in production environments.

Why Choose us?

We offer industry-leading solutions in silicon carbide and graphite crucibles.

| Our Advantages | Why It Matters |

|---|---|

| Wide Range of Sizes | From small-scale to industrial use. |

| Premium Materials | High-quality siliciumcarbide and pure graphite ensure long-term reliability. |

| Custom Solutions | Tailored designs for ladle shrouds, submerged entry nozzles, and other casting tools. |

| Expert Support | Decades of knowledge in steel manufacturing and metal casting crucibles. |

Ready to enhance your casting process? Contact us today for high-performance crucibles designed to meet your business needs!

Post time: Nov-19-2024