Silica carbide crucible

Features

The Ultimate Crucible for High-Performance Metal Melting

Are you searching for a crucible that can withstand extreme temperatures, provides excellent thermal conductivity, and offers superior corrosion resistance? Look no further—our Silicon Carbide Crucibles are engineered to deliver exceptional performance in the toughest melting environments. Whether you're working with electric or gas-fired furnaces, these crucibles are a game-changer, enhancing your operational efficiency while extending the service life of your equipment.

Key Features

- High-Temperature Resistance

Silicon carbide crucibles can easily handle temperatures exceeding 1600°C, making them ideal for melting various metals, including aluminum, copper, and precious metals. - Excellent Thermal Conductivity

With superior thermal conductivity, these crucibles allow for faster and more efficient melting cycles. This means less energy consumption and shorter production times. - Outstanding Corrosion Resistance

The inherent corrosion resistance of silicon carbide ensures a longer lifespan, even when melting reactive metals. This feature drastically reduces the need for frequent replacements, saving you money and downtime. - Low Thermal Expansion

Silicon carbide crucibles have a low coefficient of thermal expansion, meaning they maintain structural integrity even during rapid temperature changes, minimizing the risk of cracking or failure. - Stable Chemical Properties

These crucibles exhibit minimal reactivity with molten metals, ensuring the purity of your melts, especially for sensitive applications like high-purity aluminum casting.

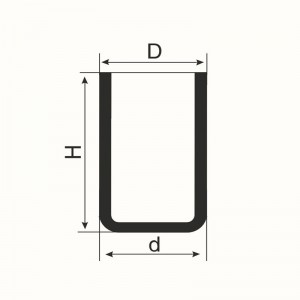

Product Specifications

| Model | Height (mm) | Outer Diameter (mm) | Bottom Diameter (mm) |

|---|---|---|---|

| CC1300X935 | 1300 | 650 | 620 |

| CC1200X650 | 1200 | 650 | 620 |

| CC650X640 | 650 | 640 | 620 |

| CC800X530 | 800 | 530 | 530 |

| CC510X530 | 510 | 530 | 320 |

Maintenance and Usage Tips

- Preheat Gradually: Always preheat your crucible slowly to avoid thermal shock.

- Cleaning: Keep the inner surface smooth and clean to avoid metal adhesion.

- Storage: Store in a dry, ventilated area to prevent moisture absorption.

- Replacement Cycle: Inspect regularly for signs of wear and tear; timely replacement ensures the best performance.

Why Choose Us?

We leverage our years of experience in metal casting to bring you silicon carbide crucibles that outperform the competition. Our expertise lies in optimizing the design and material composition to meet the most demanding industrial applications. With us, you’re not just purchasing a product—you’re partnering with a team that understands your challenges and delivers solutions tailored to your needs.

Key Advantages:

- 20% longer service life compared to industry-standard crucibles.

- Specialized in low-oxidation environments and high thermal efficiency, particularly for aluminum and copper casting industries.

- Global reach with trusted partners in Europe and North America.

FAQs

Q1: What payment terms do you offer?

We require a 40% deposit, with the balance due before delivery. We provide detailed photos of your order prior to shipment.

Q2: How should I handle these crucibles during use?

For best results, gradually preheat and clean after each use to extend their lifespan.

Q3: How long does it take to deliver?

Typical delivery times range from 7-10 days depending on the order size and destination.

Get in Touch!

Interested in learning more or requesting a quote? Contact us today to see how our Silicon Carbide Crucibles can revolutionize your metal casting operations.