Smelting Crucibles for Aluminium scrap and aluminium ingot

PRODUCT FEATURES

Superior Thermal Conductivity

The unique blend of silicon carbide and graphite ensures rapid and uniform heating, significantly cutting down on melting time.

Extreme Temperature Resistance

The unique blend of silicon carbide and graphite ensures rapid and uniform heating, significantly cutting down on melting time.

Durable Corrosion Resistance

The unique blend of silicon carbide and graphite ensures rapid and uniform heating, significantly cutting down on melting time.

TECHNICAL SPECIFICATIONS

| No | Model | OD | H | ID | BD |

| 1 | 80 | 330 | 410 | 265 | 230 |

| 2 | 100 | 350 | 440 | 282 | 240 |

| 3 | 110 | 330 | 380 | 260 | 205 |

| 4 | 200 | 420 | 500 | 350 | 230 |

| 5 | 201 | 430 | 500 | 350 | 230 |

| 6 | 350 | 430 | 570 | 365 | 230 |

| 7 | 351 | 430 | 670 | 360 | 230 |

| 8 | 300 | 450 | 500 | 360 | 230 |

| 9 | 330 | 450 | 450 | 380 | 230 |

| 10 | 350 | 470 | 650 | 390 | 320 |

| 11 | 360 | 530 | 530 | 460 | 300 |

| 12 | 370 | 530 | 570 | 460 | 300 |

| 13 | 400 | 530 | 750 | 446 | 330 |

| 14 | 450 | 520 | 600 | 440 | 260 |

| 15 | 453 | 520 | 660 | 450 | 310 |

| 16 | 460 | 565 | 600 | 500 | 310 |

| 17 | 463 | 570 | 620 | 500 | 310 |

| 18 | 500 | 520 | 650 | 450 | 360 |

| 19 | 501 | 520 | 700 | 460 | 310 |

| 20 | 505 | 520 | 780 | 460 | 310 |

| 21 | 511 | 550 | 660 | 460 | 320 |

| 22 | 650 | 550 | 800 | 480 | 330 |

| 23 | 700 | 600 | 500 | 550 | 295 |

| 24 | 760 | 615 | 620 | 550 | 295 |

| 25 | 765 | 615 | 640 | 540 | 330 |

| 26 | 790 | 640 | 650 | 550 | 330 |

| 27 | 791 | 645 | 650 | 550 | 315 |

| 28 | 801 | 610 | 675 | 525 | 330 |

| 29 | 802 | 610 | 700 | 525 | 330 |

| 30 | 803 | 610 | 800 | 535 | 330 |

| 31 | 810 | 620 | 830 | 540 | 330 |

| 32 | 820 | 700 | 520 | 597 | 280 |

| 33 | 910 | 710 | 600 | 610 | 300 |

| 34 | 980 | 715 | 660 | 610 | 300 |

| 35 | 1000 | 715 | 700 | 610 | 300 |

PROCESS FLOW

1. Precision Formulation

High-purity graphite + premium silicon carbide + proprietary binding agent.

.

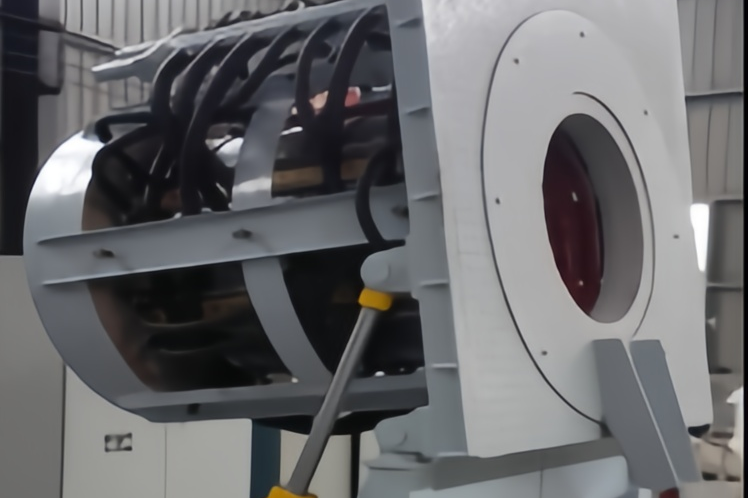

2.Isostatic Pressing

Density up to 2.2g/cm³ | Wall thickness tolerance ±0.3m

.

3.High-Temperature Sintering

SiC particle recrystallization forming 3D network structure

.

4. Surface Enhancement

Anti-oxidation coating → 3× improved corrosion resistance

.

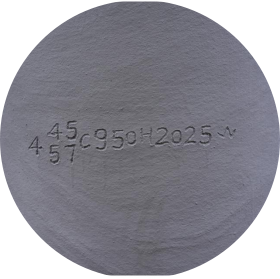

5. Rigorous Quality Inspection

Unique tracking code for full lifecycle traceability

.

6. Safety Packaging

Shock-absorbent layer + Moisture barrier + Reinforced casing

.

PRODUCT APPLICATION

Gas Melting Furnace

Induction Melting Furnace

Resistance Melting Furnace

WHY CHOOSE US

FAQS

Q1: What are the advantages of silicon carbide graphite crucibles compared to traditional graphite crucibles?

✅ Higher Temperature Resistance: Can withstand 1800°C long-term and 2200°C short-term (vs. ≤1600°C for graphite).

✅ Longer Lifespan: 5x better thermal shock resistance, 3-5x longer average service life.

✅ Zero Contamination: No carbon penetration, ensuring molten metal purity.

Q2: Which metals can be melted in these crucibles?

▸ Common Metals: Aluminum, copper, zinc, gold, silver, etc.

▸ Reactive Metals: Lithium, sodium, calcium (requires Si₃N₄ coating).

▸ Refractory Metals: Tungsten, molybdenum, titanium (requires vacuum/inert gas).

Q3: Do new crucibles require pre-treatment before use?

Mandatory Baking: Slowly heat to 300°C → hold for 2 hours (removes residual moisture).

First Melt Recommendation: Melt a batch of scrap material first (forms a protective layer).

Q4: How to prevent crucible cracking?

Never charge cold material into a hot crucible (max ΔT < 400°C).

Cooling rate after melting < 200°C/hour.

Use dedicated crucible tongs (avoid mechanical impact).

Q5: How to prevent crucible cracking?

Never charge cold material into a hot crucible (max ΔT < 400°C).

Cooling rate after melting < 200°C/hour.

Use dedicated crucible tongs (avoid mechanical impact).

Q6: What is the minimum order quantity (MOQ)?

Standard Models: 1 piece (samples available).

Custom Designs: 10 pieces (CAD drawings required).

Q7: What is the lead time?

⏳ In-Stock Items: Ships within 48 hours.

⏳ Custom Orders: 15-25 days for production and 20 days for mould.

Q8: How to determine if a crucible has failed?

Cracks > 5mm on inner wall.

Metal penetration depth > 2mm.

Deformation > 3% (measure outer diameter change).

Q9: Do you provide melting process guidance?

Heating curves for different metals.

Inert gas flow rate calculator.

Slag removal video tutorials.