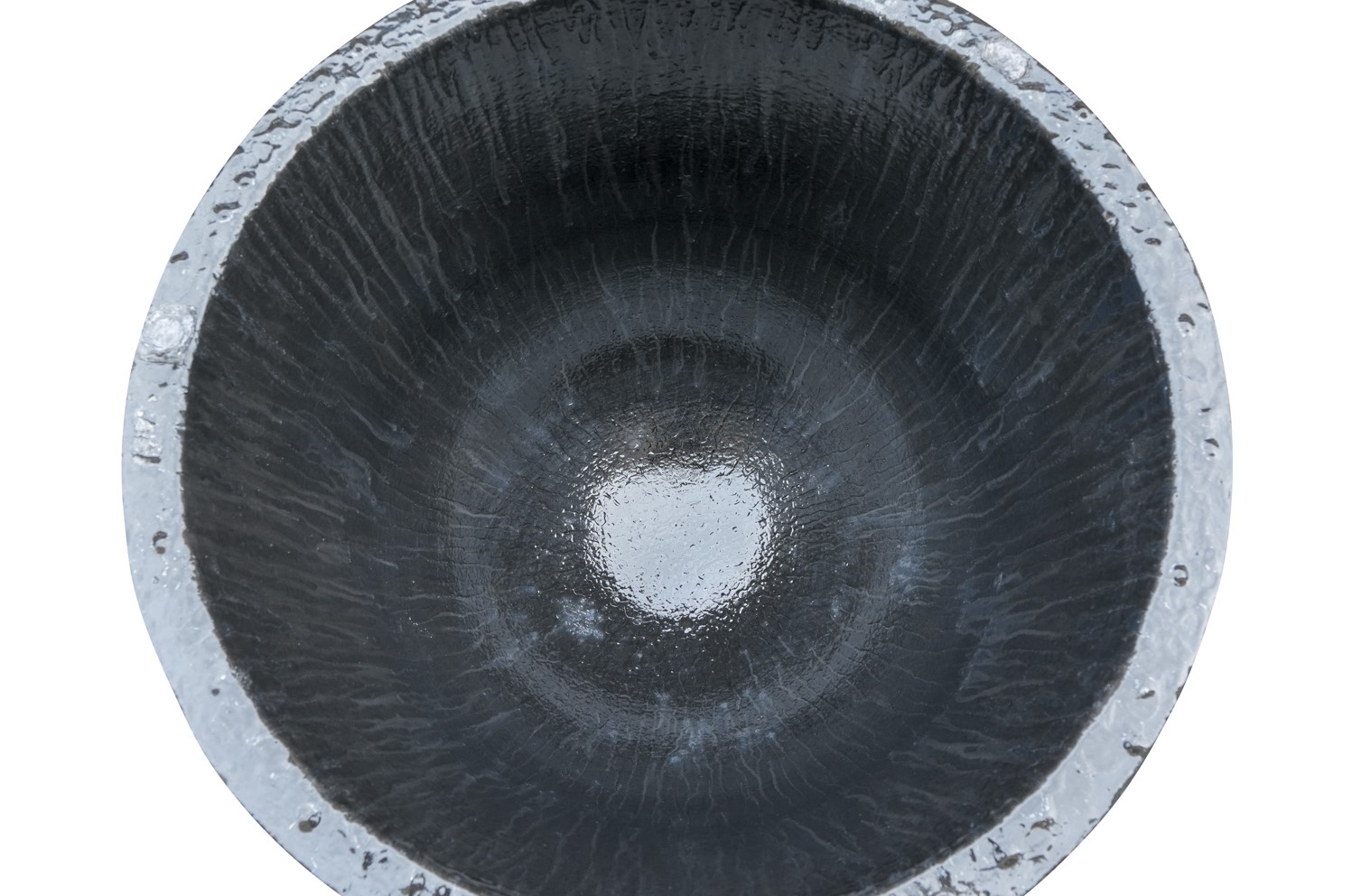

The Crucible Cover for metal melting

PRODUCT FEATURES

Rapid Melting

High thermal conductivity graphite material improves thermal efficiency by 30%, significantly reducing melting time.

Superior Thermal Shock Resistance

Resin-bonded technology withstands rapid heating and cooling, allowing direct charging without cracking.

Exceptional Durability

High mechanical strength resists physical impact and chemical erosion for a longer service life.

TECHNICAL SPECIFICATIONS

| Graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Bulk density / g·cm⁻³ | 2.20 |

| Apparent porosity / % | 10.8 |

| Crushing strength/ MPa (25℃) | 28.4 |

| Modulus of rupture/ MPa (25℃) | 9.5 |

| Fire resistance temperature/ ℃ | >1680 |

| Thermal shock resistance / Times | 100 |

| No | Model | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180# | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

PROCESS FLOW

1. Precision Formulation

High-purity graphite + premium silicon carbide + proprietary binding agent.

.

2.Isostatic Pressing

Density up to 2.2g/cm³ | Wall thickness tolerance ±0.3m

.

3.High-Temperature Sintering

SiC particle recrystallization forming 3D network structure

.

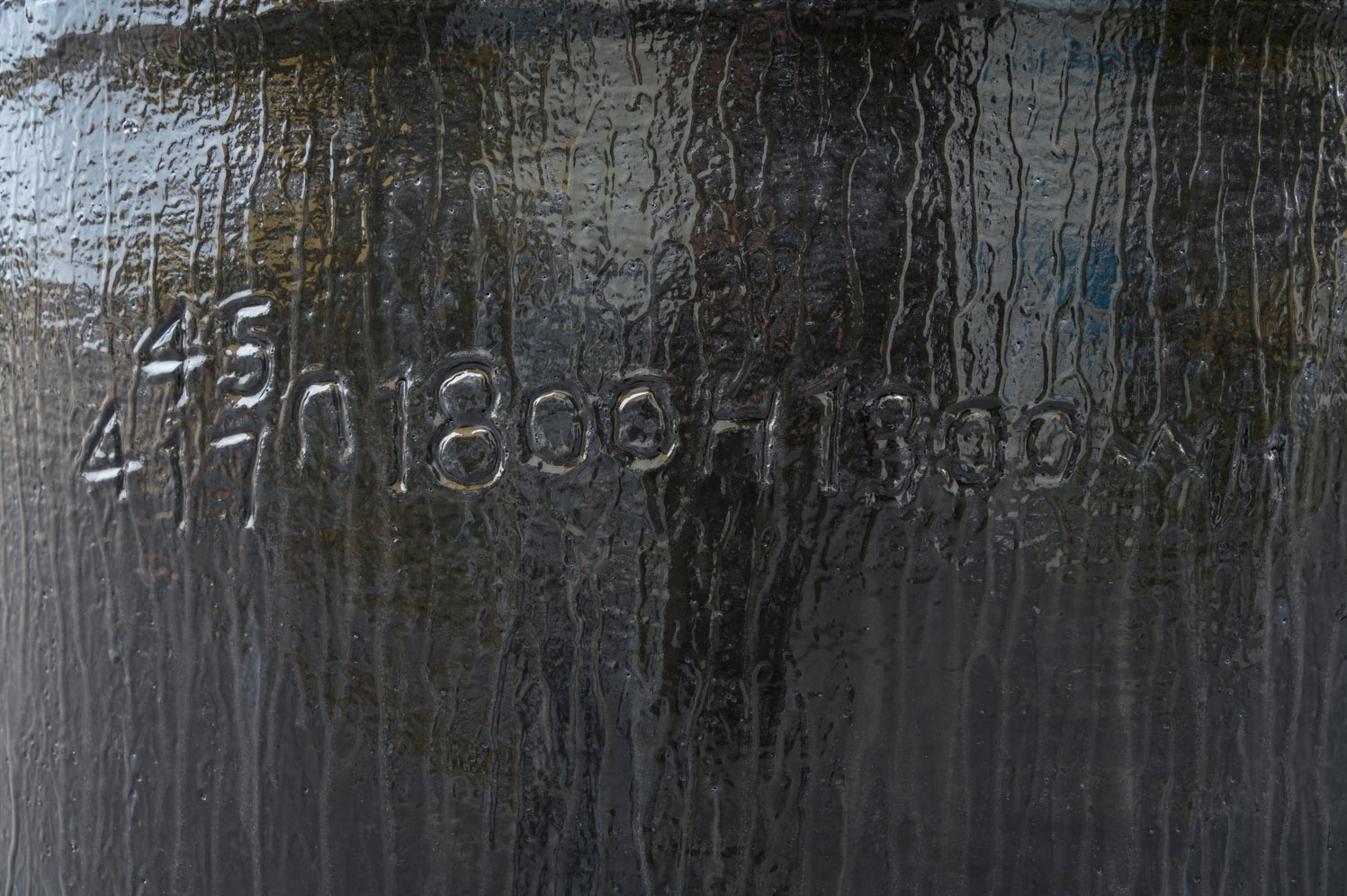

5. Rigorous Quality Inspection

Unique tracking code for full lifecycle traceability

.

4. Surface Enhancement

Anti-oxidation coating → 3× improved corrosion resistance

.

6. Safety Packaging

Shock-absorbent layer + Moisture barrier + Reinforced casing

.

PRODUCT APPLICATION

Suitable for most non-ferrous metals

Melt Aluminium

Melt Copper

Melt Gold

WHY CHOOSE US

FAQS

Q1: Can The Crucible Cover reduce energy costs?

A: Absolutely! It reduces heat loss, cutting energy consumption by up to 30%.

Q2: What furnaces are compatible?

A: It’s versatile—suitable for induction, gas, and electric furnaces.

Q3: Is graphite silicon carbide safe for high temperatures?

A: Yes. Its thermal and chemical stability makes it perfect for extreme conditions.

Q4: How to prevent crucible cracking?

Never charge cold material into a hot crucible (max ΔT < 400°C).

Cooling rate after melting < 200°C/hour.

Use dedicated crucible tongs (avoid mechanical impact).

Q5: How to prevent crucible cracking?

Never charge cold material into a hot crucible (max ΔT < 400°C).

Cooling rate after melting < 200°C/hour.

Use dedicated crucible tongs (avoid mechanical impact).

Q6: What is the minimum order quantity (MOQ)?

Standard Models: 1 piece (samples available).

Custom Designs: 10 pieces (CAD drawings required).

Q7: What is the lead time?

⏳ In-Stock Items: Ships within 48 hours.

⏳ Custom Orders: 15-25 days for production and 20 days for mould.

Q8: How to determine if a crucible has failed?

Cracks > 5mm on inner wall.

Metal penetration depth > 2mm.

Deformation > 3% (measure outer diameter change).

Q9: Do you provide melting process guidance?

Heating curves for different metals.

Inert gas flow rate calculator.

Slag removal video tutorials.